This kind of factory sliding door adopts a multi-leaf spliced assembly structure. It solves the problem that the container size cannot meet the transportation needs of large-volume door leaves due to the large volume of customized aluminum-framed factory doors. At the same time, the strength of factory sliding door is ensured to the greatest extent, so that their size can reach a maximum of 15m wide * 8m high.

share:

- product description

- Product installation process

Factory sliding door introduction

Kaixiang's (kx-door's)patented aluminum frame factory sliding door uses upper load-bearing aluminum alloy tracks, silent nylon groove wheels, and no lower track design. It is not affected by the harsh environment on the ground and always maintains smooth sliding.

It does not rust, has good sealing performance, is silent, and has strong environmental adaptability, forming huge advantages that traditional galvanized iron frame factory doors cannot match.

Six major features of the product

1.Not rust 2.Easy installation 3.Push smoothly 4.Good sealing 5.Light weight 6.No maintenance required

Factory sliding door detail

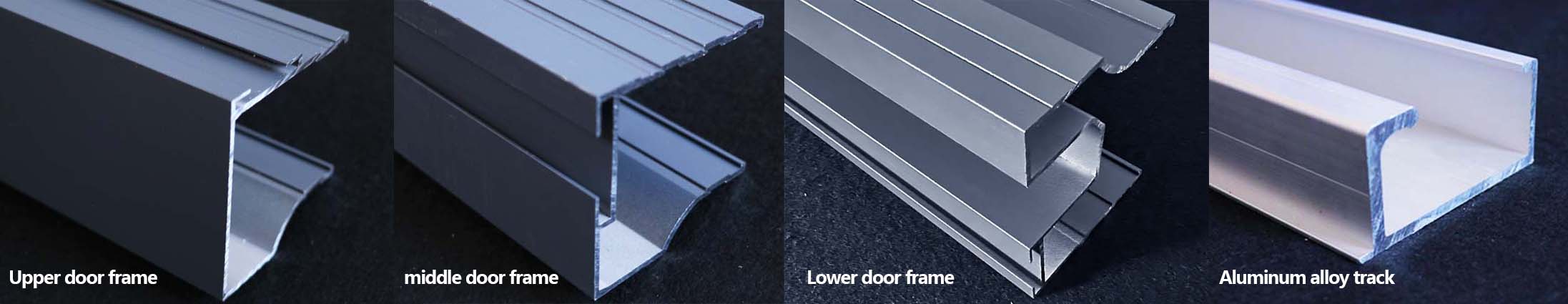

1. Door frame material:

Fluorocarbon sprayed aluminum alloy material/aluminum oxide alloy material

2.Door panel filling:

Polystyrene flame retardant foam/ glass wool/ polyurethane foam/ rock wool/ aluminum honeycomb

Door panel thickness:

100/75/50mm

3.Factory door motor:

Load-bearing DC brushless motor, developed by kx-door(kaixiang)

4.Door limit size:

Width ≤15m, height ≤8m

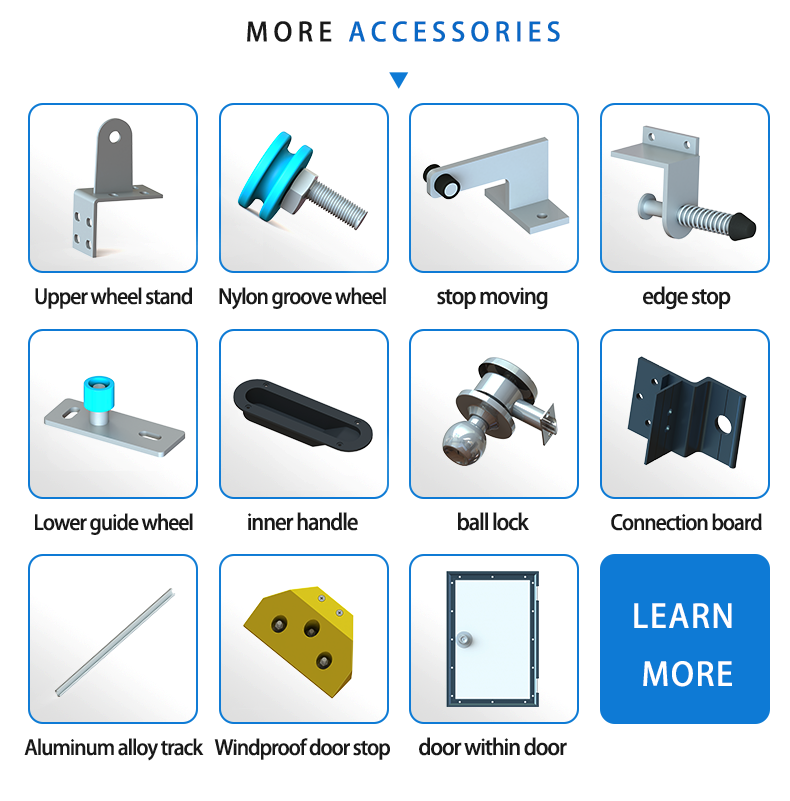

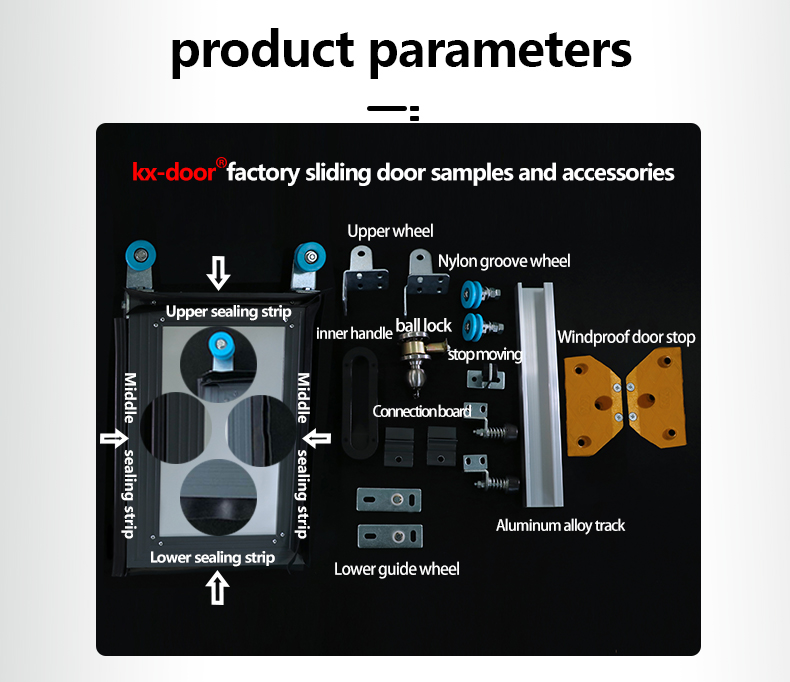

Product accessory display

1.Display of kx-door ’s factory sliding door body details

①upper wheel stand②nylon groove wheel③stop moving④edge stop⑤lower guide wheel⑥inner handle⑦ball lock⑧connection board ⑨aluminum alloy track ⑩windproof door stop⑪door within door

(factory sliding door)

2.Real photos of physical accessories

①Brand:kx-door(kaixiang)

②Material:Aluminum alloy

③Shape:Economical model/patented model/Deluxe version

④Door frame color:Industrial gray/oxidized silver Door

⑤Door panel color:Regular white gray

⑥Door panel thickness:100mm/75mm/50mm

⑦Door panel padding :Flameretardant foam/glasswool/polyurethanefoam/rock wool

⑧Service life:Design service life is more than 15 years

⑨Production cycle:About 1 5 working days

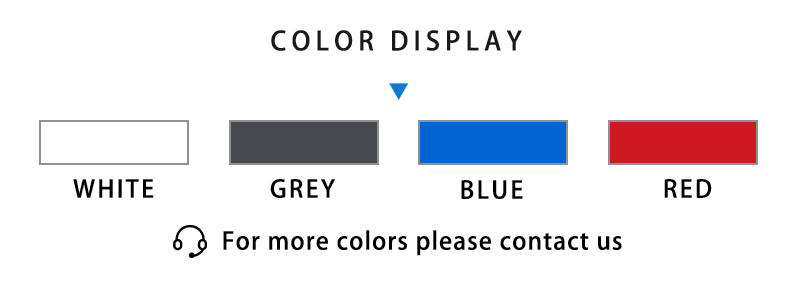

3.Door panel color selection

①white ②grey ③blue ④red

_11.jpg)

kx-door's installation process:

We usually equip different factory sliding door accessories according to the structure of your different walls:

For example:1. Steel structure wall 2. Civil engineering wall

1.Steel structure wall

①Steel structure walls need to weld angle iron or square tubes to the load-bearing beams in advance, with a welding interval of ≤1.2m to facilitate the fixation of the aluminum alloy track.

②Then use the national standard drill tail steel wire to drill holes on the aluminum alloy track and fix it on the reserved angle iron or square tube.

Videos:

2. Civil engineering wall

① Civil construction walls need to be drilled on the aluminum alloy track and wall in advance, and the optimal spacing between openings is 1-1.2m.

②Then use national standard internal expansion screws to fix the aluminum alloy track

.gif)